Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Magnet NdFeB telah diterapkan secara luas pada motor mini yang menggerakkan perangkat 3C (komputer, komunikasi, dan elektronik konsumen). Hal ini terutama disebabkan oleh sifat magnetnya yang tak tertandingi termasuk kerapatan fluks yang tinggi, ketahanan yang tinggi terhadap demagnetisasi, dan stabilitas suhu yang sangat baik. Hasilnya, magnet NdFeB menawarkan keunggulan signifikan dibandingkan magnet keramik tradisional dan AlNiCo pada motor mini yang memerlukan rasio torsi terhadap volume tinggi. W Kami akan membahas berbagai bentuk magnet NdFeB yang digunakan pada motor untuk perangkat 3C dan menganalisis tren pasar di bidang ini. Kami juga akan membahas keuntungan menggunakan magnet NdFeB dibandingkan bahan lain dan menyoroti kekuatan Zhejiang Zhongke Magnetic Industry Co. ., Ltd. dalam pembuatan magnet ini.

+86-15857968349

+86-15857968349

Bentuk Magnet NdFeB yang digunakan dalam Perangkat 3C

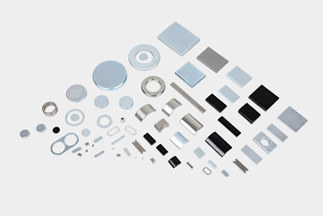

Magnet NdFeB untuk digunakan pada perangkat 3C biasanya tersedia dalam beberapa bentuk termasuk cakram, silinder, balok, dan cincin. Setiap bentuk memiliki keunggulan unik tergantung pada aplikasi motor tertentu. Misalnya, magnet berbentuk cakram ideal untuk aplikasi yang memerlukan permukaan magnet datar dan stabil untuk penentuan posisi yang akurat. Magnet silinder umumnya digunakan pada motor fluks aksial, dimana magnet dimagnetisasi sepanjang sumbunya dan menghasilkan medan magnet radial. Magnet cincin memiliki lubang di tengahnya dan cocok untuk digunakan pada motor DC brushless, dimana rotor biasanya dipasang pada poros dan berputar mengelilingi stator. Magnet berbentuk balok serbaguna dan digunakan dalam berbagai aplikasi.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

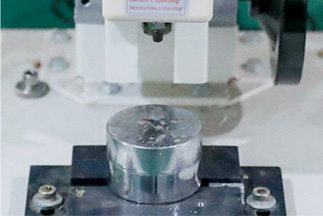

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Keuntungan Berbagai Bentuk Magnet NdFeB

Magnet NdFeB berbentuk cakram memiliki rasio luas permukaan terhadap volume yang tinggi, sehingga ideal untuk aplikasi kecepatan tinggi yang mengharuskan motor membuang panas dengan cepat.

Magnet silinder, sebaliknya, memiliki distribusi medan magnet yang lebih seragam dan ideal untuk aplikasi di mana motor memerlukan rasio torsi terhadap volume yang tinggi.

Magnet cincin menawarkan kekuatan radial yang sangat baik, sehingga ideal untuk digunakan pada motor DC brushless berperforma tinggi.

Magnet berbentuk balok serbaguna dan dapat digunakan dalam berbagai aplikasi motor.

Tren Pasar Magnet NdFeB di Perangkat 3C

Keuntungan dari Zhejiang Zhongke Magnetic Industry Co., Ltd. di bidang Manufaktur Magnet NdFeB

Zhejiang Zhongke Magnetik Industry Co, Ltd. telah menjadi produsen magnet NdFeB terkemuka selama lebih dari 12 tahun. Perusahaan telah banyak berinvestasi dalam penelitian dan pengembangan serta telah mengembangkan beberapa teknologi eksklusif yang meningkatkan kinerja magnet NdFeB. Beberapa keunggulan Zhejiang Zhongke Magnetic Industry Co.,Ltd. dalam pembuatan magnet NdFeB termasuk:

1. Proses manufaktur tingkat lanjut: Perusahaan menggunakan proses manufaktur canggih untuk menghasilkan magnet NdFeB berkualitas tinggi yang memenuhi permintaan pasar perangkat 3C.

2. Bahan berkualitas tinggi: Zhejiang Zhongke Magnetic Industry Co., Ltd. hanya menggunakan bahan mentah berkualitas tinggi untuk memproduksi magnet NdFeB, memastikan bahwa magnet tersebut memiliki sifat magnet yang sangat baik dan sangat tahan lama.

3. Kustomisasi: Perusahaan menawarkan magnet NdFeB yang disesuaikan untuk memenuhi kebutuhan unik pelanggannya.

4. Produksi skala besar: Perusahaan memiliki kapasitas produksi yang terus meningkat setelah pembangunan pabrik baru, yang memungkinkannya memproduksi magnet NdFeB dalam jumlah besar, menjadikannya pemasok ideal untuk pasar 3C bervolume tinggi.

Magnet NdFeB telah menjadi komponen penting dalam motor mini yang menggerakkan perangkat 3C. Penggunaan magnet NdFeB pada perangkat 3C diperkirakan akan meningkat secara signifikan di tahun-tahun mendatang, didorong oleh meningkatnya permintaan akan motor berperforma tinggi yang dapat beroperasi di lingkungan yang keras. Berbagai bentuk magnet NdFeB menawarkan keunggulan unik tergantung pada aplikasi motor spesifik. Zhejiang Zhongke Magnetik Industry Co, Ltd. telah memantapkan dirinya sebagai produsen magnet NdFeB terkemuka, berkat proses manufakturnya yang canggih, bahan berkualitas tinggi, dan kemampuan penyesuaian.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.